IN625 Nickel Base Alloy Powder Inconel 625 Powder

Paglalarawan ng Produkto

Ang Huarui high temperature nickel-based alloy na IN625 powder ay isang na-optimize na powder, lalo na angkop para sa SLM forming technology, kabilang ang EOS Selective Laser Melting Equipment (EOSINT M Series), Concept Laser Melting Equipment, Renishaw Laser Melting Equipment, American 3D Systems Laser Melting Equipment, at mga instituto at instituto ng domestic research.

Sa pamamagitan ng iba't ibang pamamahagi ng laki ng butil, maaari din itong hatiin sa injection molding powder, laser cladding powder, spraying powder, hot isostatic pressing powder at iba pa.

Pagtutukoy

| Chemical Composition(%) ng Inconel 625 Powder | ||||||

| Cr | Co | Al | Mo | Mn | Ti | Nb |

| 20-23 | ≤1.0 | ≤0.4 | 8.0-10 | ≤0.5 | ≤0.4 | 3.15-4.15 |

| Fe | C | Si | P | S | O | Ni |

| ≤0.5 | ≤0.1 | ≤0.5 | ≤0.015 | ≤0.15 | ≤0.02 | Bal |

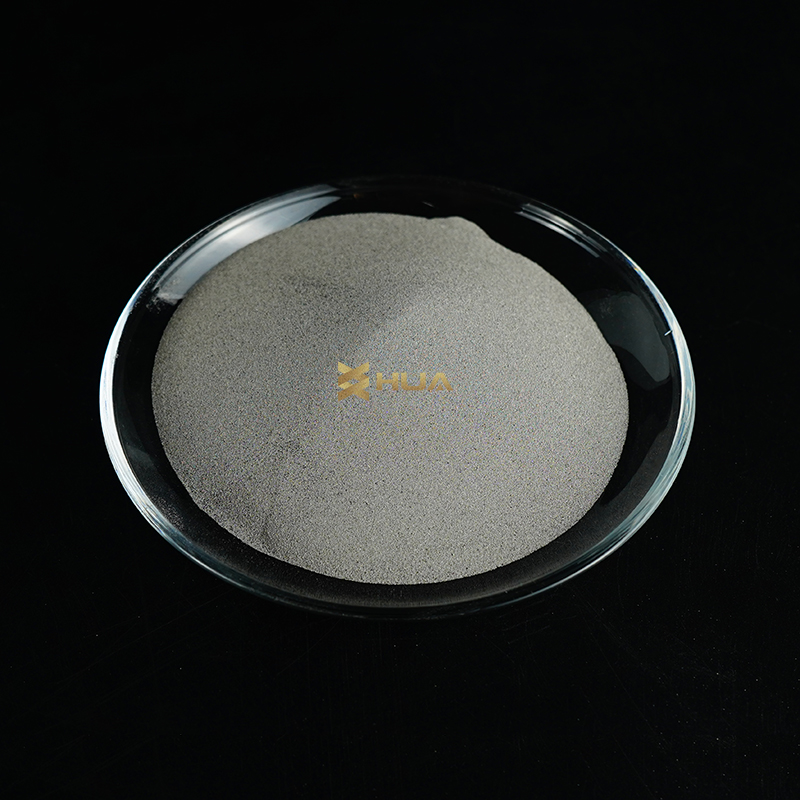

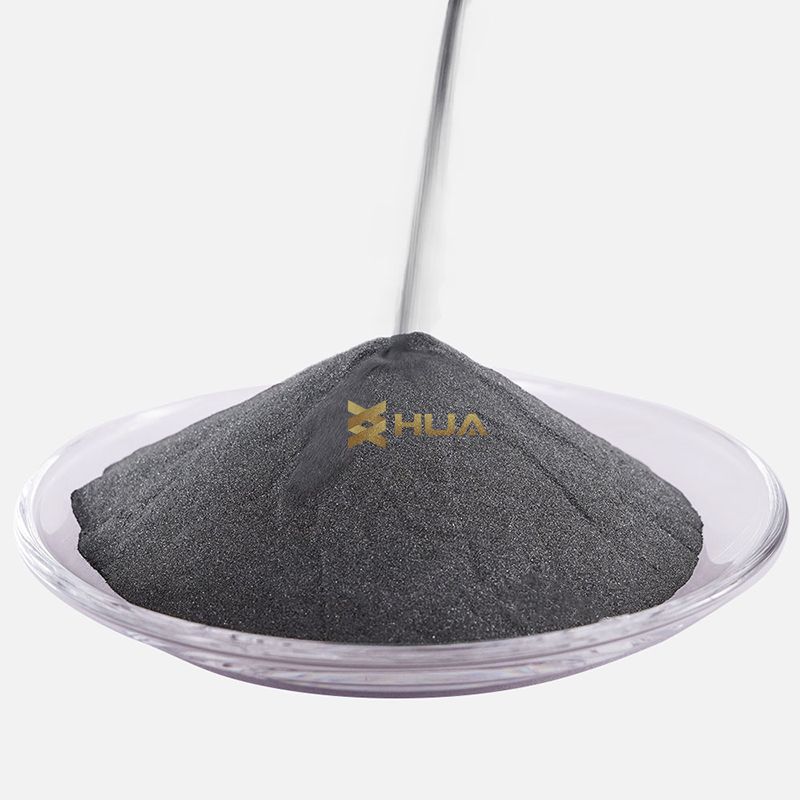

| Malinaw na Densidad: 4.50g/cm3 | Kulay: kulay abo | Hugis: spherical | ||||

| Laki ng Particle | 15-53micron;45-105micron;45-150micron | |||||

| Inconel 625 Powder Properties | ||||||

| Laki ng saklaw | 0~25um | 0~45um | 15~45um | 45~105um | 75~180um | |

| Morpolohiya | Pabilog | Pabilog | Pabilog | Pabilog | Pabilog | |

| Pamamahagi ng Laki ng Particle | D10: 6um | D10: 9um | D10: 14um | D10: 53um | D10: 78um | |

| D50:16um | D50: 28um | D50: 35um | D50: 69um | D50: 120um | ||

| D90: 23um | D90: 39um | D90: 45um | D90: 95um | D90: 165um | ||

| Kakayahang dumaloy | N/A | ≤30S | ≤28S | ≤16S | ≤18S | |

| Maliwanag Density | 4.2g/cm3 | 4.5g/cm3 | 4.4g/cm3 | 4.5g/cm3 | 4.4g/cm3 | |

| Nilalaman ng Oxygen (wt%) | O: 0.06~0.018wt% , pamantayan ng ASTM : ≤0.02 wt% | |||||

| 3D printing Gas Atomized Inconel 625 Powder na may pinakamagandang presyo | ||||||

| (mababang oxygen, mataas na sphericity at magandang pagkalikido) | ||||||

Aplikasyon

1. HVOF

2. Plasma coating

3. 3D printing / additive manufacturing

4. powder welding

5. metal injection molding

6. mainit na isostatic

Kaugnay na Mga Produkto

Nagbibigay din kami ng Inconel 718 powder, NiCr powder, NiAl powder, Ni20-Ni65 powder, maligayang pagdating sa pagtatanong!